MadeinFusina

La scultura in plexiglas Arco di Carlo Bonato

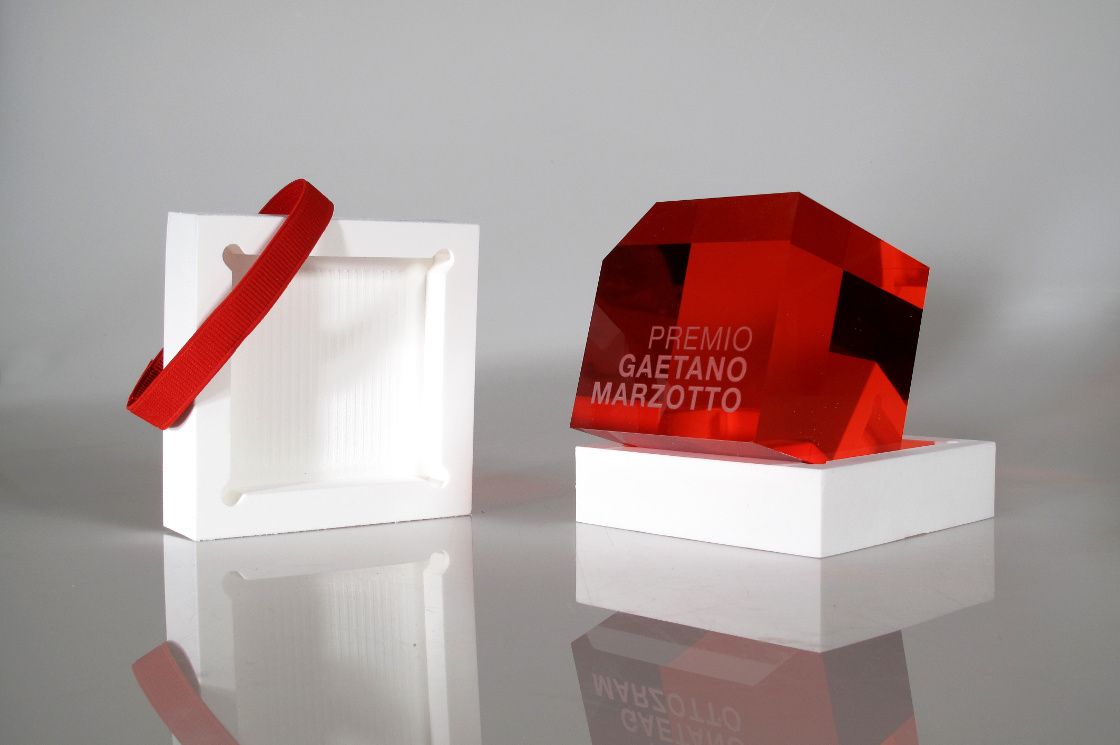

Il cubo in plexiglas rosso inciso al laser realizzato da Fusina per il premio Gaetano Marzotto nel 2015

Il temporary showroom realizzato a Milano da Fusina per il brand di abbigliamento OffWhite

Plexiglas: 5 good reasons to use it in displays and fittings

If plexiglas displays and fittings often amazes people, it is thanks to the particular characteristics of such material, but also thanks to the creativity and the skills of those who work with it.

Very thin or thick, completely transparent or fully coloured, shiny or satiny… the range of effects that one can get with plexiglas is so wide that sometimes it is hard to recognize it in all its shapes.

It is often employed instead of glass, which is really similar, and it can be used in a larger number of contexts; from the domestic to the industrial and commercial one. You can find it within furniture flat surfaces, canopies, shelves, partitions, accident preventions, advertising signs. But the most spectacular features of this material can be seen in design solutions: fair fittings, shopwindows and shops, modular displays, table displays, wall displays, showcases, plates, boxes and PoP elements (Point of Purchase).

What is plexiglas?

The technical name of plexiglass is polymethilmethacrylate (PMMA), which indicates a particular kind of resin. The development of the chemical process that gave birth to plexiglass dates back to 1928 in Germany, and made its appearance in the market in 1993 on the initiative of the chemist Otto Roehm and its industry.

During the Seventies the founder of Fusina, Carlo Bonato, with his wife Lena, was one of the pioneers in the plexiglass manufacturing, by applying on this material some techniques that come from the field of mechanics to achieve spectacular results. The sculpture “Arco”, precisely by Carlo Bonato, which became Fusina’s logo, was exhibited last year at the exhibition 1946-1975 – the roots of innovation.

5 good reasons to use plexiglas in displays and fittings

According to the needs, plexiglas can be manufactured in a melted form or extruded: the first process is obtained by the cooling of the semi-liquid material inside a mould, while in the second process the plexiglass “paste” is transformed into sheets with a fixed thickness. There are different advantages: the thickness of extruded plexiglass is the same all over the sheet (it is more suitable for works that require very precise measurements), while the melted one, more “pure” and transparent, is ideal to create works of art.

In any case, there are at least 5 good reasons to choose plaxiglass displays and other retail design solution:

It is like glass, but it is more practical: the excellent transparency combined with a good resistance, to the atmospheric agents too, and lightness, makes plexiglas ideal for creating large and small exhibit supports, such as shop windows, glass cases, display cases, boxes and furniture pieces for shops and exhibition spaces.

It can create different colour changing effects: if different pigments pastes are added, plexiglas can produce a wide range of lightning and colour effects, from semi-transparent to fluorescent.

Besides being engraved, it can be printed: thanks to devices such as the Mimaki flatbed printer that is used by Fusina, high-quality logos, drawings and texts can be reproduced on a plexiglas support.

It is a thermoplastic material: therefore, it can be bent and shaped through heating, bu it doesn’t require extremely high temperatures.

It can be recycled: although it is constituted by plasic, plexiglas can be 100% recyclable. Fusina has always cared deeply about using environmentally friendly materials: our industrial waste are employed again for white street paints (the ones that we see on the tarmac).

But it isn’t over: another really evocative effect concerns the “floating” objects inside plexiglas, which can be obtained by manufacturing them with melted material. But if we focus on surfaces, walls and fittings, mirror plexiglass gives it great lightness, just like the one used by Fusina in the Offwhite temporary showroom in Milan.

The innovative use of plexiglas as material to shape creativity, in addition to brands and agencies practical needs was always in the DNA of Fusina.

Experience has always taught us that having a precious and high quality material on hand in our job is of great importance, but it’s not enough: when we check the measurements of a sheet with accuracies below the millimeter, or when we polish the plates one by one, we know how much that manual skill and craftsmen “patience”, beside the technical skills, is an essential ingredient to be successful.

Archive MadeinFusina

May 03 2023 | MadeinFusina

The FusinaLab Bestiary

Small scenes and wunderkammer recreate a compendium of animals in colored plexiglass in the FusinaLab laboratory.

January 27 2022 | MadeinFusina

Contemporary Psychedely for retail

Daily explorations, material exercises as solicitations for the definition of unique objects of its kind. Interpretations that go beyond the schemes and that want to transfer alterations, sensory...

October 20 2020 | MadeinFusina

Registration Certificate for FusinaLab

In the process of developing and building the brand value, we inform you that the FusinaLab brand has been registered with EUIPO. FusinaLab is now registered...

April 16 2018 | MadeinFusina

The history of Plexiglas, from shiny glass to design object

When a material born by chance becomes a fundamental object of design Nowadays, Plexiglas is one of the most widespread and versatile material in circulation, used in industry, in the commercial...